At present, the mainstream power batteries in China are divided into two types based on the different positive electrode materials: lithium iron phosphate batteries and ternary batteries. It is precisely because of the different positive electrode materials that there are significant differences in performance between these two types of batteries.

Lithium iron phosphate material has a stable structure and good thermal stability, and its cyclic performance and safety are superior to ternary materials; Ternary materials have high energy density, but due to their unstable structure during charging and discharging, they are prone to phase transformation, resulting in poorer cycling performance compared to lithium iron phosphate; The thermal stability of ternary materials is poor, so the safety hazards of ternary batteries are higher than those of lithium iron phosphate. In domestic and foreign reports of accidents related to electric vehicle combustion and explosion, the number of safety accidents caused by ternary batteries is significantly higher than that of lithium iron phosphate batteries.

1¡¢ Experimental process

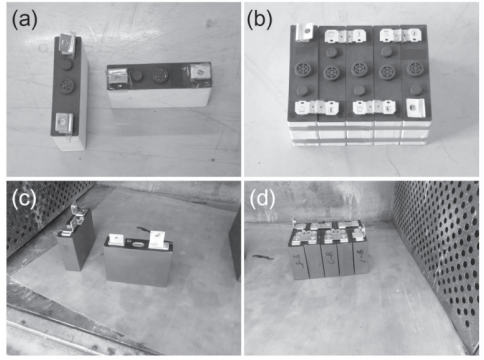

This article tests the single cell cycle life, room temperature discharge capacity, and room temperature discharge capacity of 75Ah lithium iron phosphate and ternary NCM622 batteries, as well as the room temperature discharge capacity and room temperature rate performance of modules (5 cells in series), according to the relevant testing regulations of GB/T 31484-2015 "Requirements and Test Methods for Cycle Life of Power Batteries for Electric Vehicles" and GB/T 31486-2015 "Requirements and Test Methods for Electrical Performance of Power Batteries for Electric Vehicles". The photos of the battery cells and modules are shown in Figure 1. The individual weight of lithium iron phosphate battery is 1.81kg, and the module weight is 9.05kg; The individual weight of the ternary battery is 1.34kg, and the module weight is 6.70kg.

Figure 1 Commercial lithium iron phosphate battery (a) monomer and (b) module; Commercial ternary batteries (a) monomers and (b) modules

1.1 Performance testing of battery cells

The upper limit of the charging voltage for lithium iron phosphate batteries is 3.8V, and the discharge termination voltage is 2V; The upper limit of the charging voltage for the lithium iron phosphate battery module is 19V. The upper limit of the charging voltage for a ternary battery is 4.2V, and the discharge termination voltage is 3.0V; The upper limit of the charging voltage for the ternary battery module is 21.5V.

1.1.1 Single cycle life test

a) Discharge at 1I1 (I1=75A) to the termination voltage;

b) Set aside for 30 minutes;

c) Charge with a constant current of 1I1 until the voltage limit is reached and then switch to constant voltage charging. Stop charging when the charging current drops to 0.05I1;

d) Set aside for 30 minutes;

e) Record the discharge capacity at the discharge termination condition of 1I1;

f) Cycle continuously for 500 times according to b) to e).

1.1.2 Single cell room temperature discharge capacitance test

a) Charge with a constant current of 1I1 until the voltage limit is reached and switch to constant voltage charging. Stop charging when the charging current drops to 0.05I1 and let it stand for 1 hour;

b) At room temperature, the battery is discharged at a current of 1I1 until it reaches the termination voltage;

c) Measure discharge capacity and record discharge specific energy;

d) Repeat steps a) to c) 5 times. If the range of the results of three consecutive tests is less than 3% of the rated capacity, the test can be terminated early and the average of the last three test results can be taken.

1.2 Battery module performance testing

1.2.1 Module room temperature discharge capacity test

a) The battery module (5 individual cells connected in series) is charged at a constant voltage of 1I1 until the voltage limit is reached. When the charging current drops to 0.05I1, the charging stops. If the voltage of any individual cell exceeds the termination voltage by 0.1V during the charging process, the charging stops. After charging, it is left to stand for 1 hour;

b) At room temperature, the battery is discharged at a current of 1I1 until any individual cell voltage reaches the discharge termination voltage;

c) Measure discharge capacity and discharge specific energy;

d) Repeat steps a) to c) 5 times. If the range of the results of three consecutive tests is less than 3% of the rated capacity, the test can be terminated early and the average of the last three test results can be taken.

1.2.2 Module room temperature rate discharge performance test

a) The battery module is charged at a rate of 1I1 until the voltage limit is reached and then switched to constant voltage charging. When the charging current drops to 0.05I1, the charging stops. If the voltage of a single battery exceeds the termination voltage by 0.1V during the charging process, the charging stops. After charging, it is left idle for 1 hour;

b) At room temperature, the battery module discharges at a current of 3I1 until any individual cell voltage reaches the discharge termination voltage;

c) Measure discharge capacity.

2¡¢ Results and Discussion

The cycle life test results of commercial lithium iron phosphate batteries and ternary battery monomers are shown in Figure 2. The first week discharge capacity of lithium iron phosphate battery is 77.80Ah (mass specific capacity 42.98Ah/kg), and after 500 cycles, the discharge capacity is 72.01Ah (mass specific capacity 39.78Ah/kg), with a capacity retention rate of 92.56%. The first week discharge capacity of the ternary battery is 77.82Ah (mass specific capacity 58.07Ah/kg), and after 500 cycles, the discharge capacity is 70.69Ah (mass specific capacity 52.75Ah/kg), with a capacity retention rate of 90.84%.

It can be seen that the cycling stability of lithium iron phosphate batteries is higher than that of ternary batteries, which have more advantages in specific capacity and higher rated voltage than lithium iron phosphate batteries. Therefore, it can be foreseen that the energy density of ternary batteries is higher than that of lithium iron phosphate batteries, and subsequent discharge capacity tests will specifically verify this.

The discharge capacity curves obtained from the discharge capacity tests of commercial lithium iron phosphate batteries and ternary batteries are shown in Figure 3. The discharge capacities of lithium iron phosphate batteries for three cycles are 78.56 Ah, 78.73 Ah, and 78.79 Ah (specific capacities of 43.40 Ah, 43.50 Ah, and 43.53 Ah/kg, respectively). According to the standard, the average value of 78.69 Ah (specific capacity of 43.48 Ah/kg) is taken as the discharge capacity. The discharge capacities of the ternary battery for three cycles are 76.98, 77.78, and 77.89 Ah (specific capacities of 57.38, 58.04, and 58.13 Ah/kg, respectively), and the average value of 77.55 Ah (specific capacity of 57.87 Ah/kg) is taken as the discharge capacity.

Figures 3 (a) and 3 (b) show the three discharge capacity curves of lithium iron phosphate and ternary batteries, respectively. Lithium iron phosphate batteries have a gentle discharge voltage platform between 3.25 and 3.15V, while ternary batteries have a discharge platform between 4.05 and 3.35V, with a wider voltage platform. The three discharge energies of lithium iron phosphate were recorded as 248.90 Wh (specific energy 137.51 Wh/kg), 248.15 Wh (specific energy 137.10 Wh/kg), and 247.31 Wh (specific energy 136.64 Wh/kg), with an average specific energy of 137.08 Wh/kg; The three discharge energies of the ternary battery are 278.78Wh (specific energy 208.04Wh/kg), 282.36Wh (specific energy 210.72Wh/kg), and 282.88Wh (specific energy 211.10Wh/kg), with an average specific energy of 209.95Wh/kg. It can be seen that due to the higher specific capacity and voltage platform of ternary batteries compared to lithium iron phosphate batteries, the specific energy of commercial ternary batteries is higher than that of lithium iron phosphate batteries.

The discharge capacity curves obtained from the discharge capacity tests of commercial lithium iron phosphate batteries and ternary battery modules (both in series with 5 units) are shown in Figure 4. The discharge capacities of the lithium iron phosphate battery module for three cycles are 76.91Ah, 77.72Ah, and 77.88Ah, respectively. According to the standard regulations, the average value of 77.47Ah is taken as the discharge capacity; The discharge capacities of the ternary battery module for three cycles are 80.80Ah, 80.97Ah, and 81.02Ah, respectively. The average value of 80.93Ah is taken as the measured discharge capacity.

The rate discharge curves of commercial lithium iron phosphate batteries and ternary battery modules are shown in Figure 5, which shows the discharge curve of fully charged battery modules at a 3C rate (225A). The discharge capacity of the lithium iron phosphate battery module is 76.19Ah, which is 98.3% of the initial capacity (module discharge capacity test result); The discharge capacity of the ternary battery is 80.14Ah, which is 99.2% of the initial capacity. This indicates that there is no significant difference in the discharge capacity of commercial lithium iron phosphate and ternary batteries at high 3C rates compared to 1C rates (1I1 current).